The system structure with control algorithm of motor drive based on a microcontroller is shown in Figure 10. Adjusting the proportional gain of speed controller, K ps, can be applied to meet the requirements of the overshoot for the overall control system. The system is inherently stable since the maximum phase angle of the complete control system is −90 °. From the approximation of current loop crossover frequency and the corner frequency of PI controller, the complete speed-controlled drive system is redrawn in Figure 9.

In addition, the 3-dB frequency is obtained from the integrator time delay of PI controller is usually chosen to be smaller than the rotor frequency. As we observe the speed control loop, the open-loop transfer function of the speed response has three poles, which can be obtained from the integrator time delay constant, current loop time delay, and the load time constant, respectively.įor a speed-controlled drive system, the 3-dB frequency generated from the current loop time delay is always designed to be higher than the rotor frequency. Where K ps is the proportional gain and K is is the integrator gain. Due to the high development of power semiconductors, the control module such as microcontrollers, DSPs, ARMs, or FPGA are widely adopted according to the complexity functions for the motor drive requirements. The control module is the core controller of the overall electrical drive. It is required for the closed-loop control. Sensing module is employed to detect rotor position, rotor speed, motor current, or motor terminal voltages. Depending on the energy from required by the input power source and motors, AC to DC converters (rectifiers or controlled rectifiers), DC to DC converters (step-up converters or step-down converters), inverters, and cycloconverters are commonly used in the electrical drives design. The converter converts the electrical energy of the input source in the form suitable to the motor. Most commonly used electrical motors are DC motors, brushless DC motors, induction motors, permanent magnet synchronous motors, stepper motors, and switched reluctance motors.

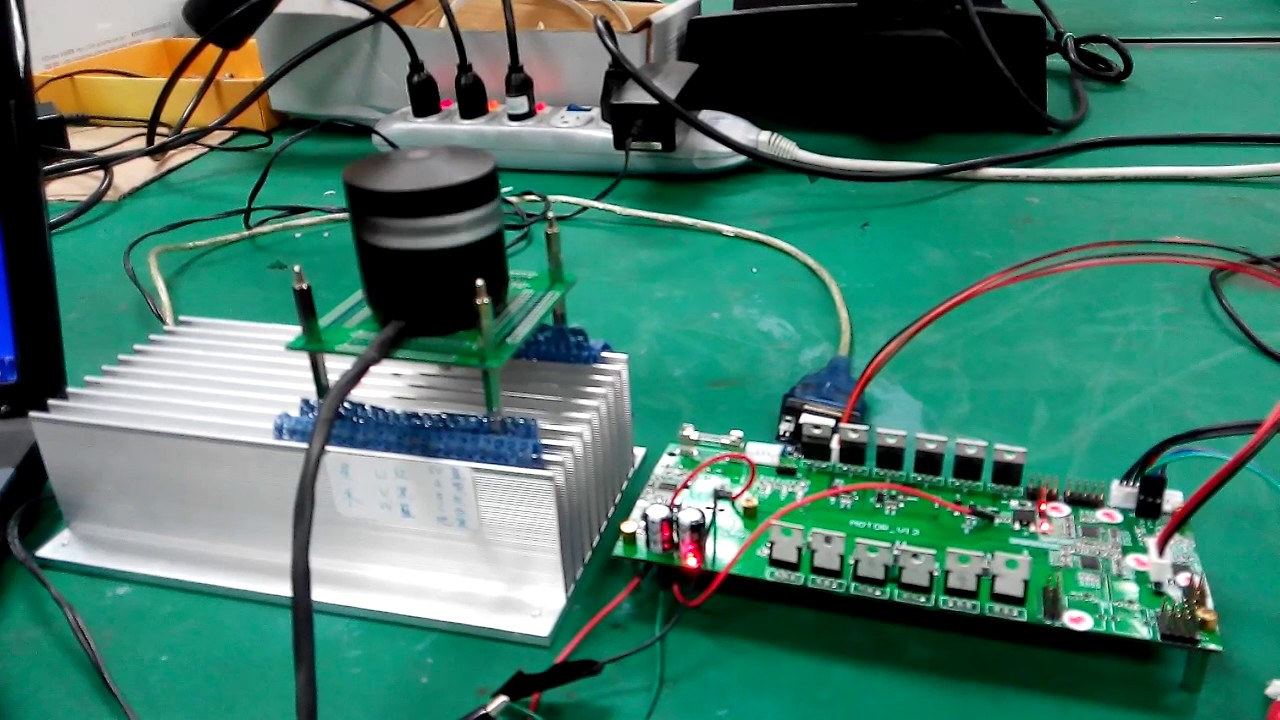

The motor has the characteristics required by the load and the capability to transfer the energy from the source to the load. Load can be washing machine, range hood, pumps, air conditioners, fans, machine tools, or electric drills. Power source can be supplied by AC line supply or DC battery. It mainly consists of power source, converter, motor, load, sensing module, and control module. Finally, a conclusion is made in section five.Ī simplified block diagram of an electrical drive is shown in Figure 2. The experimental results are also presented and discussed.

#Bldc motor driver controller software

The hardware and software design of a motor drive based on a microcontroller is given in section four. The control design of a speed-controlled motor drive is described in section three. The 120° conduction and 180° conduction of switching device for an inverter are also described and illustrated. The dynamic model for brushless dc motor is derived and explained in detail in section two. At the beginning of chapter, the fundamental of energy conversion for electric machines is introduced. Therefore, this chapter will focus on the design and implementation of a motor drive as well as its realization of control algorithm. Brushless DC motor (BLDC) and permanent magnet AC synchronous motors drives have many advantages such as high efficiency, small size, less rotor losses, and fast torque response over the induction motor drives. The high performance of control and fast dynamic response of electric machines can be achieved via motor drive because of high development of semiconductors such as the microcontroller and power transistors. The electric machines have been applied to the industrial and commercial areas for several decades.

0 kommentar(er)

0 kommentar(er)